Mastering Assembly Cable Design: Building Reliability from the Inside Out

The assembly cable is more than a bundle of wires; it is the nervous system of complex electronic systems across aerospace, defense, telecommunications, and industrial applications. In today’s high-tech world, performance depends on what connects everything together. Whether transmitting data, power, or control signals, the quality and precision of an assembly cable directly determine system reliability.

Yet, the process of designing and manufacturing these assemblies is often misunderstood or underestimated. It involves engineering precision, material science, and strict adherence to industry standards. Companies that master this process achieve measurable advantages in product durability, performance, and safety.

What Is an Assembly Cable?

An assembly cable is a custom-engineered system that connects multiple components within an electrical or electronic product. It combines conductors, insulation, shielding, and connectors to achieve specific performance outcomes. Unlike off-the-shelf wiring, assembly cables are built to meet unique application needs, from high-frequency communication systems to mission-critical aerospace electronics.

These assemblies ensure that electrical signals travel cleanly and efficiently under demanding conditions. Every element, from the conductor’s gauge to the connector’s plating, affects how a system performs in the field. In industries like aerospace, automotive, and medical technology, even small deviations in assembly quality can lead to significant failures.

Common types of assemblies include:

Cable Harness Assembly

A cable harness (or wire harness {link to wire harness article}) assembly organizes multiple wires into a single protective sheath or bundle. This approach simplifies installation, improves safety, and reduces the risk of electrical shorting. Harness assemblies are common in vehicles, industrial equipment, and control systems where space is limited and reliability is critical.

Coax Cable Assembly

A coax cable assembly transmits high-frequency signals with minimal interference. It features a central conductor surrounded by dielectric insulation and a shield to prevent signal loss. Coax assemblies are widely used in communication systems, radar, and broadcasting applications.

Custom Cable Assemblies

Custom cable assemblies are engineered for specialized performance needs, combining specific wire types, shielding materials, and connector configurations. These are ideal for equipment that operates in harsh environments or requires precise electrical characteristics.

Aerospace Cable Assemblies

In aviation and defense applications, aerospace cable assemblies must withstand extreme temperatures, vibration, and electromagnetic interference. These assemblies often meet rigorous standards such as MIL-DTL-38999 or AS9100. High-quality aerospace assemblies are tested for signal integrity, tensile strength, and long-term endurance.

Engineering a Better Connection

Designing a reliable assembly cable requires careful balance among electrical, mechanical, and environmental factors. Every design decision, from conductor type to connector fit, contributes to the overall performance and longevity of the system.

The conductor material is the foundation of performance. Copper remains the industry standard due to its excellent conductivity, but tinned or silver-plated versions offer enhanced corrosion resistance in harsh or high-humidity environments.

Shielding is equally important, serving as the barrier against electromagnetic interference and signal degradation. Foil and braided shields are commonly used to maintain clean data transmission, especially in high-frequency or data-intensive applications.

Insulation and jacket materials play a critical role in determining a cable’s flexibility, temperature tolerance, and resistance to environmental stress. Materials such as PTFE, PVC, and silicone are chosen based on the specific conditions in which the assembly will operate. Finally, connector selection ensures both mechanical integrity and electrical compatibility. Choosing the right connector guarantees a stable interface with mating equipment, reducing the likelihood of failures caused by vibration or repeated use.

The goal is to create a system that performs consistently under electrical load, temperature fluctuations, and mechanical stress. When every design element is engineered with precision, the result is an assembly cable that delivers long-term resilience and reliability.

Manufacturing Excellence: Quality Through Every Step

Production of cable harness assemblies and related systems requires both precision and consistency. Manufacturers use automated stripping, crimping, and soldering equipment to ensure uniformity. Each connection point undergoes testing for continuity and pull strength before final assembly.

Leading manufacturers also implement process traceability, documenting materials, procedures, and quality checks for every cable. This level of control reduces variability and supports compliance with aerospace and defense standards. According to the IPC/WHMA-A-620 standard, acceptable wire terminations and soldering practices are essential benchmarks for ensuring product safety and reliability.

High-quality assembly also relies on testing. Advanced techniques like time-domain reflectometry (TDR) and hipot testing verify insulation integrity and signal performance. These measures ensure that custom cable assemblies perform exactly as designed before integration into final systems.

Meeting the Demands of High-Performance Applications

Each industry places unique demands on cable harness assemblies and interconnect systems.

- Aerospace and Defense: Requires lightweight, high-temperature, and EMI-resistant materials to meet stringent flight and safety standards.

- Telecommunications: Demands precise impedance control for high-frequency signal integrity in coax cable assembly design.

- Industrial Automation: Prioritizes flexibility, chemical resistance, and ease of maintenance for long-term reliability.

- Medical Equipment: Requires biocompatible and sterilizable materials that meet regulatory standards.

In these environments, failure is not an option. Well-designed assemblies not only prevent downtime but also contribute to measurable performance gains across mission-critical systems.

The Innovation Frontier: Smarter, Smaller, Stronger

As electronic systems become more compact and powerful, the demand for custom cable assemblies continues to grow. Engineers are integrating miniaturized connectors, flexible circuit layers, and embedded sensors to enhance system intelligence.

Emerging technologies such as fiber-optic integration and hybrid copper-fiber assemblies are redefining what is possible. These innovations allow higher data throughput, reduced weight, and better EMI shielding, all key advantages for next-generation aerospace and industrial systems.

Research from the National Institute of Standards and Technology (NIST) highlights that advances in cable manufacturing precision and material science are critical to maintaining signal integrity in high-speed digital systems. As frequencies rise, small improvements in cable construction can yield large performance gains.

Quality, Safety, and Compliance

Quality assurance is non-negotiable in aerospace cable assemblies and related products. Compliance with IPC, AS9100, and MIL-spec standards ensures that every assembly meets or exceeds performance and safety requirements.

Environmental testing, including vibration, temperature cycling, and humidity exposure, verifies that assemblies perform reliably over extended lifecycles. Each of these tests reinforces confidence that cables will function safely in mission-critical environments.

For OEMs and systems integrators, partnering with a trusted manufacturer means gaining more than a product; it means gaining a proven process.

The Power of Precision in Every Connection

Every assembly cable plays a critical role in overall system performance. When designed and manufactured with precision, it ensures consistent signal transmission, mechanical stability, and long-term reliability. Poorly constructed cables, on the other hand, can lead to electrical faults, data interference, or costly downtime that disrupts operations.

True reliability comes from attention to detail. The right materials, proper shielding, and precise assembly methods guarantee performance under stress. In an industry where efficiency and safety depend on connectivity, precision engineering is what separates dependable systems from those that fail.

Building Confidence Through Quality

Exceptional results require both technical expertise and rigorous manufacturing control. High-quality assembly cables are not just components; they are the foundation of reliable communication, power, and data systems across industries. Each connection must meet exact specifications to perform seamlessly in real-world conditions.

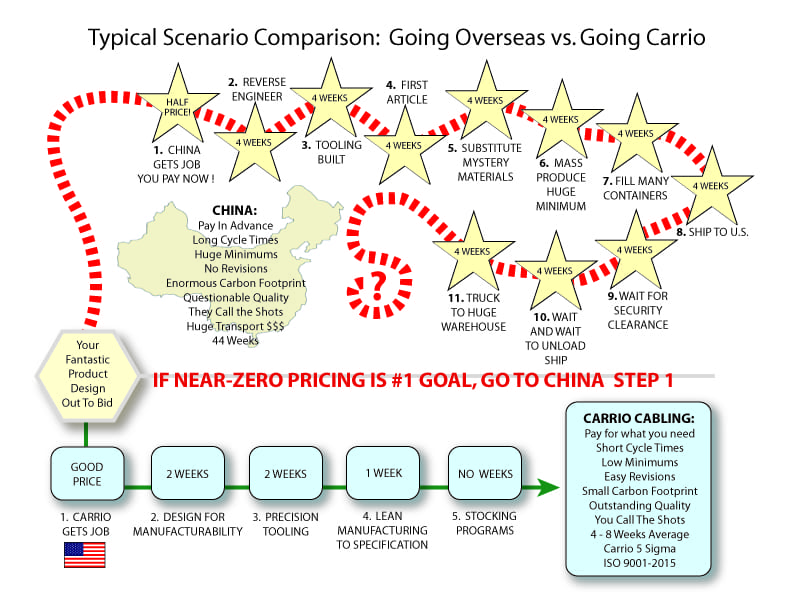

Carrio Cabling brings this level of precision and commitment to every project. Our engineers design and manufacture custom cable assemblies, including cable harness assemblies, coax cable assembly, and aerospace cable assemblies, all built for performance, compliance, and durability.

Contact Carrio Cabling today to learn how our solutions can strengthen your next project from the inside out.